In 2017, the automotive market grew for the fourth year in a row to reach 97.3 million vehicles (+ 2.4% vs. 2016). This trend vindicates the decision of car manufacturers who chose to partially or totally outsource their supply chain. Changes in market size, the acceleration of vehicle launches and the arrival of new technologies are all real challenges. How can we use logistics to make industrial tools more efficient in this state of constant evolution? Here are four ways to become more flexible by outsourcing your supply chain.

Overcome variation constraints

Externalizing, which is by nature flexible, is a solution for overcoming variations. However, it relies on partners who have the appropriate abilities: flexible service, mobilization ability, geographic coverage, and the capacity to manage complex flows. GEODIS works with major parts and car manufacturers across the globe, as we use our research department and management tools to optimize transport strategy and secure factory production at the best cost. "GEODIS sets an example as a leader in the truck market,” says Olivier Marchegay, Global Account Director for the GEODIS Automotive Market. “We coordinate intercontinental flows via all types of transport solutions, including road, air, sea and rail."

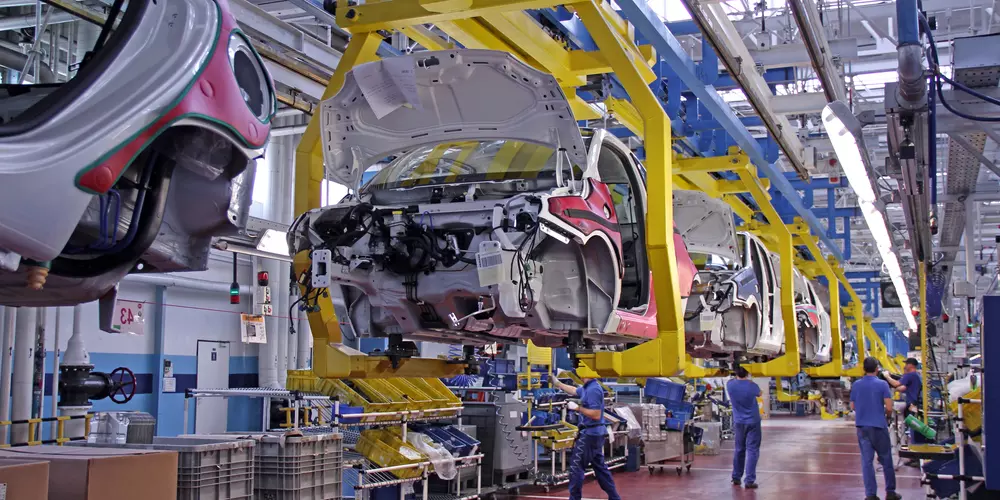

Optimize production supply

GEODIS is the supplier for several assembly plants in France, representing is the third largest automotive producer in Europe with 2.2 million vehicles produced in 2017 (+ 7% vs. 2016). Operators, drivers, rolling stock, information systems: our resources are 100% dedicated to sites that can be reached 7 days a week, 24 hours a day. Being on-call is part of our value-added services. GEODIS drivers are also trained in safety protocols so that they can do their own factory unloading and reloading.

Benefit from global support

Producing automobiles requires the mastery of international flows. While the automobile industry is organized on a global scale via regional clusters, intercontinental flows are vital, and the necessity for precision and synchronization remains the same for both regional and international levels. GEODIS supplies car and parts manufacturers via sea, rail, road and air routes all around the world while providing visibility, control and flexibility. For example, GEODIS supplies Mexican factories with shipments from Asia and Europe, taking care of the entire logistics process, from the order all the way to payment. We have also set up a consolidation railway service between Europe and Asia, perfectly adapted to the constraints of the automotive sector.

Improve productivity

Regardless of location, the needs of automobile and automotive equipment manufacturers remain identical when it comes to productivity. This calls for constant questioning and innovation, including in the area of industrial processes. In this sense, a leading European car manufacturer has completely outsourced its supply chain management to GEODIS. Our service combines the order, optimizes transportation plans, follows assembly instructions for the customer along with the final delivery, all in perfect synchronization with the production chain. As a result, the manufacturer can optimize their flexibility and simplify their upstream logistics by working with a single partner on the production line.

"This level of integration is made possible thanks to our industrial know-how and our ability to offer continuous improvement through a LEAN approach and a regular reengineering of production processes," says Marchegay.

Source: OICA, ACEA

by

by

by

by